Ventilatori assiali e centrifughi

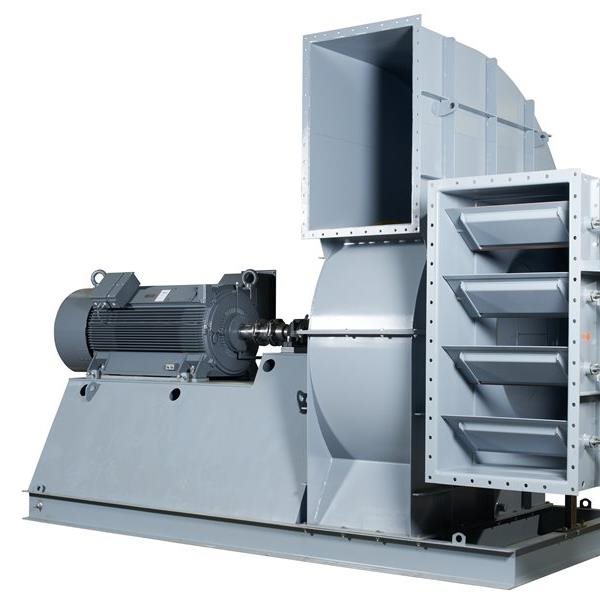

I ventilatori assiali e centrifughi altamente efficienti e affidabili di Howden supportano una vasta gamma di processi industriali che richiedono il flusso di aria o gas.

Da oltre 100 anni Howden progetta ventilatori per soddisfare le esigenze industriali e continua a essere leader a livello mondiale nell’aumento dell’efficienza energetica, nel miglioramento dell’affidabilità e nella riduzione dei costi di durata del servizio per i clienti. Che si tratti di posizioni critiche in processi industriali pesanti o in applicazioni ausiliarie nell’industria leggera, Howden ha un ventilatore adatto.

L’aria è uno degli ingredienti più comuni dei processi industriali e i ventilatori Howden sono parte integrante di tali processi fin dalla rivoluzione industriale.

I nostri ventilatori possono essere utilizzati a tiraggio forzato o indotto per spingere o aspirare attraverso il processo i volumi d’aria specificati. In grado di gestire un’ampia gamma di volumi e pressioni, offrono prestazioni affidabili per garantire una produzione continua.

Obiettivo: fornire flussi d’aria affidabili a volumi e pressioni selezionati in ogni fase del processo con la massima efficienza.

Tipici processi serviti

I settori da noi serviti utilizzano molti tipi di gas all’interno dei processi produttivi e anche come sottoprodotto del processo.

I nostri ventilatori sono fondamentali nei processi continui che utilizzano gas, dall’azoto all’idrogeno, dai gas nobili ai gas di scarico. Sono progettati per durare e fornire prestazioni elevate, resistendo agli effetti dei gas corrosivi e contenendo il gas in modo sicuro all’interno del ventilatore e del processo.

Obiettivo: movimentare in modo sicuro ed efficiente flussi di gas a volumi e pressioni selezionati all’interno e in uscita da ciascun processo.

Tipici processi servitiHowden dispone anche di una gamma completa di compressori per gas, nel caso in cui le esigenze di flusso e pressione del gas siano superiori a quelli adatti ai nostri ventilatori.

I ventilatori Howden sono utilizzati per mantenere condizioni di lavoro e di trasporto sicure e confortevoli, sia all’interno di impianti industriali che nel sottosuolo.

I nostri ventilatori aspirano o spingono grandi volumi d’aria attraverso il sistema di ventilazione, oltre a estrarre aria di scarico, gas e potenzialmente fumo dagli spazi protetti.

Obiettivo: movimentare in modo efficiente i flussi d’aria necessari all’interno del sistema, sia in continuo che in caso di emergenza.

Tipici processi serviti

I ventilatori Howden costituiscono una parte essenziale dei sistemi di raffreddamento di processi e utenze che utilizzano l’aria per dissipare il calore nell’atmosfera. I nostri prodotti sono rinomati per l’ottima efficienza e la bassa rumorosità, che consentono agli operatori di progettare la soluzione migliore in relazione ai requisiti di capacità di raffreddamento, allo spazio in loco e alle normative sul rumore.

I nostri ventilatori aspirano o spingono grandi volumi d’aria attraverso scambiatori di calore con raffreddamento ad aria (ACHE/ACHX), condensatori raffreddati ad aria (ACC) e torri di raffreddamento. Vengono utilizzati anche all’interno di macchinari pesanti per mantenere i motori a temperature di esercizio ottimali.

Obiettivo: rimuovere il calore da un processo o da un’apparecchiatura operativa in modo efficiente ed entro i limiti di rumore consentiti.

Tipici processi serviti

L’aria è uno degli ingredienti più comuni dei processi industriali e i ventilatori Howden sono parte integrante di tali processi fin dalla rivoluzione industriale.

I nostri ventilatori possono essere utilizzati a tiraggio forzato o indotto per spingere o aspirare attraverso il processo i volumi d’aria specificati. In grado di gestire un’ampia gamma di volumi e pressioni, offrono prestazioni affidabili per garantire una produzione continua.

Obiettivo: fornire flussi d’aria affidabili a volumi e pressioni selezionati in ogni fase del processo con la massima efficienza.

Tipici processi serviti

I settori da noi serviti utilizzano molti tipi di gas all’interno dei processi produttivi e anche come sottoprodotto del processo.

I nostri ventilatori sono fondamentali nei processi continui che utilizzano gas, dall’azoto all’idrogeno, dai gas nobili ai gas di scarico. Sono progettati per durare e fornire prestazioni elevate, resistendo agli effetti dei gas corrosivi e contenendo il gas in modo sicuro all’interno del ventilatore e del processo.

Obiettivo: movimentare in modo sicuro ed efficiente flussi di gas a volumi e pressioni selezionati all’interno e in uscita da ciascun processo.

Tipici processi servitiHowden dispone anche di una gamma completa di compressori per gas, nel caso in cui le esigenze di flusso e pressione del gas siano superiori a quelli adatti ai nostri ventilatori.

I ventilatori Howden sono utilizzati per mantenere condizioni di lavoro e di trasporto sicure e confortevoli, sia all’interno di impianti industriali che nel sottosuolo.

I nostri ventilatori aspirano o spingono grandi volumi d’aria attraverso il sistema di ventilazione, oltre a estrarre aria di scarico, gas e potenzialmente fumo dagli spazi protetti.

Obiettivo: movimentare in modo efficiente i flussi d’aria necessari all’interno del sistema, sia in continuo che in caso di emergenza.

Tipici processi serviti

I ventilatori Howden costituiscono una parte essenziale dei sistemi di raffreddamento di processi e utenze che utilizzano l’aria per dissipare il calore nell’atmosfera. I nostri prodotti sono rinomati per l’ottima efficienza e la bassa rumorosità, che consentono agli operatori di progettare la soluzione migliore in relazione ai requisiti di capacità di raffreddamento, allo spazio in loco e alle normative sul rumore.

I nostri ventilatori aspirano o spingono grandi volumi d’aria attraverso scambiatori di calore con raffreddamento ad aria (ACHE/ACHX), condensatori raffreddati ad aria (ACC) e torri di raffreddamento. Vengono utilizzati anche all’interno di macchinari pesanti per mantenere i motori a temperature di esercizio ottimali.

Obiettivo: rimuovere il calore da un processo o da un’apparecchiatura operativa in modo efficiente ed entro i limiti di rumore consentiti.

Tipici processi serviti

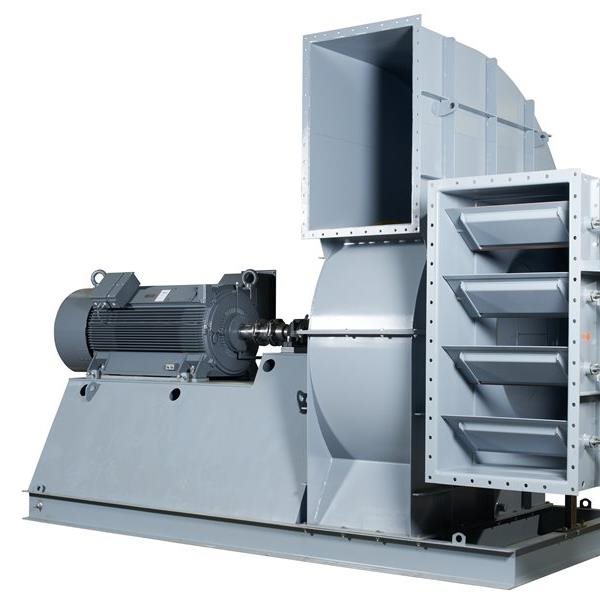

Howden vanta un pedigree ingegneristico sviluppato nell’arco di centinaia di anni attraverso il marchio Howden originale e quelli che si sono aggiunti all’azienda come Sirocco, Sturtevant, Buffalo Forge, Covent, Turbowerke Meissen, Solyvent-Ventec, Voith e Nordisk.

I nostri ventilatori vanno da quelli configurati a quelli completamente progettati per soddisfare un’ampia varietà di richieste dei clienti. La nostra capacità ingegneristica ci permette di avere le conoscenze, l’esperienza e la capacità di adattare e sviluppare nuovi progetti per requisiti specifici.

Tutti i ventilatori sono progettati per massimizzare l’efficienza di funzionamento. A seconda dell’applicazione e del funzionamento alcuni raggiungono un’efficienza superiore al 90%. I ventilatori sono conformi agli standard industriali richiesti per ogni applicazione, ad esempio API, ATEX, certificazioni nucleari.

Gamma di prodotti

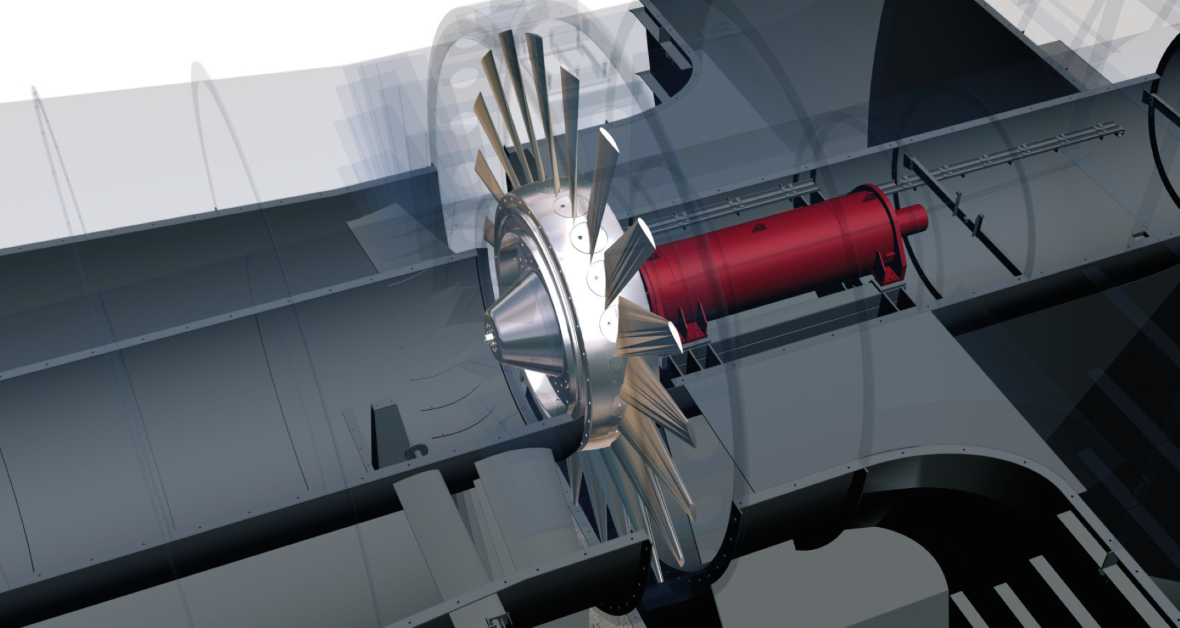

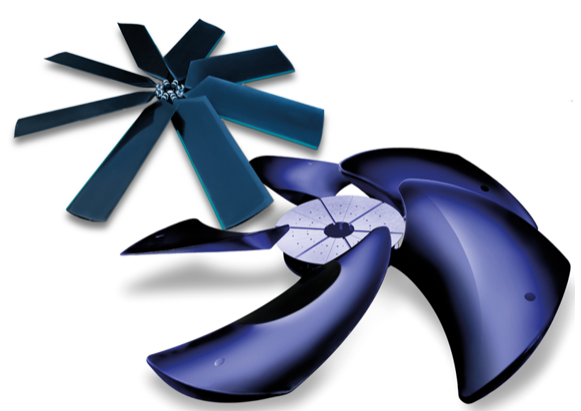

La gamma di ventilatori assiali comprende una serie di prodotti sviluppati da diversi marchi attuali e storici di Howden per offrire una copertura completa delle esigenze di portata e pressione di livello industriale.

Questa gamma ci permette di affrontare molte applicazioni con configurazioni alternative, verticali o orizzontali, e diverse opzioni di controllo delle portate, dal passo regolabile manualmente al passo variabile e agli azionamenti a frequenza variabile.

Tutti i ventilatori sono costruiti secondo standard elevati per garantire un funzionamento efficiente e una manutenzione ridotta con un servizio affidabile.

Gamma di prodotti

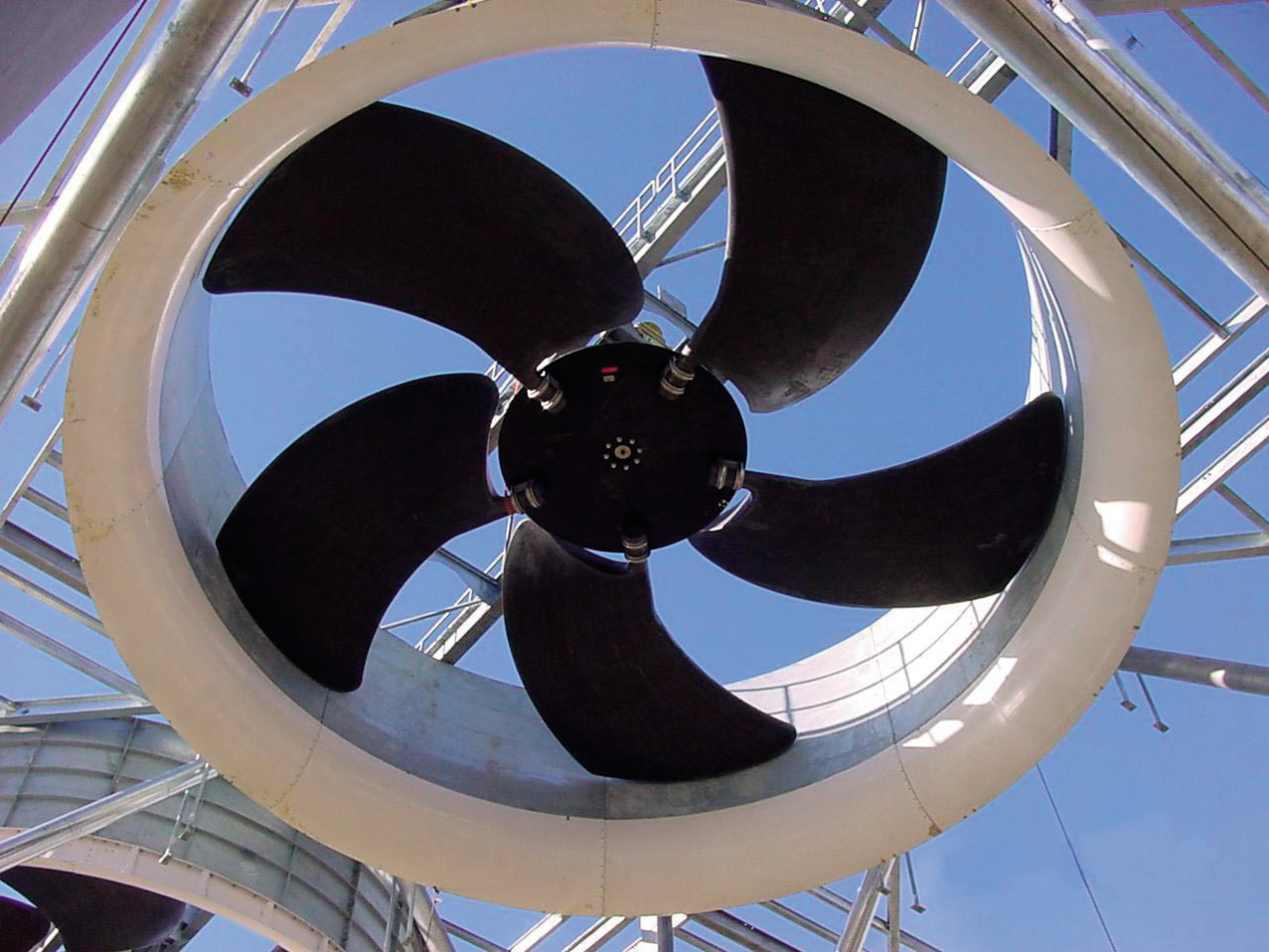

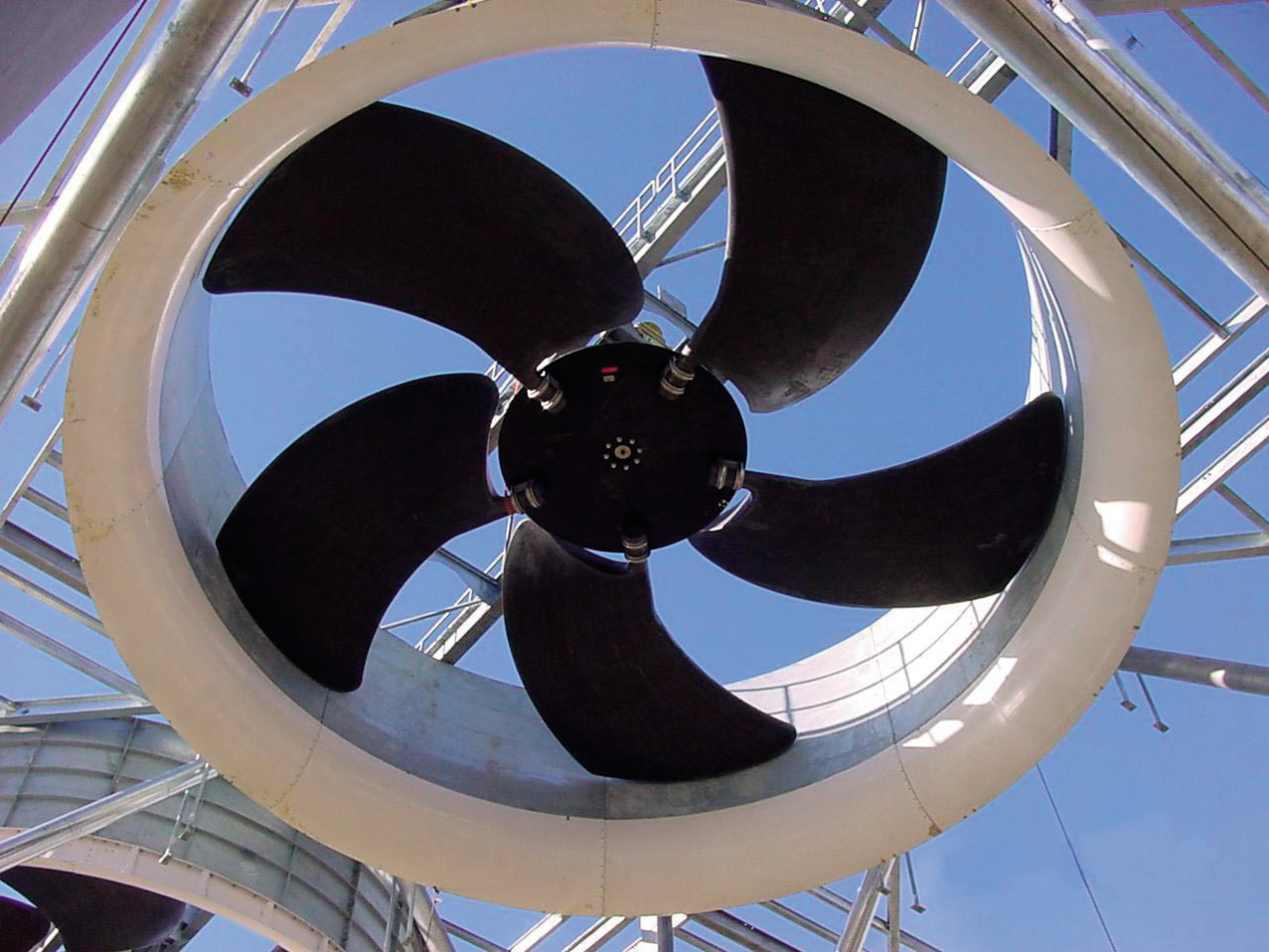

La nostra gamma di ventole di raffreddamento è composta dalle serie D, E, SX e FPX e offre prestazioni eccezionali in termini di efficienza e livelli di rumorosità in una serie di settori diversi, dagli impianti di alimentazione, petroliferi e del gas agli impianti di produzione industriale leggera, ai data center, agli edifici commerciali e ai motori di macchinari industriali.

La gamma di ventilatori copre un’ampia serie di prestazioni con una bassa caduta di pressione fino a 250 Pa e un’elevata portata d’aria fino a 3000 m3/s. Offre livelli di rumorosità da bassi a bassissimi per massimizzare l’uscita nel rispetto delle normative del sito.

Per ulteriori informazioni sulla gamma, visita la nostra pagina dedicata ai ventilatori di raffreddamento e accedi alla nostra documentazione di marketing.

I nostri ventilatori vanno da quelli configurati a quelli completamente progettati per soddisfare un’ampia varietà di richieste dei clienti. La nostra capacità ingegneristica ci permette di avere le conoscenze, l’esperienza e la capacità di adattare e sviluppare nuovi progetti per requisiti specifici.

Tutti i ventilatori sono progettati per massimizzare l’efficienza di funzionamento. A seconda dell’applicazione e del funzionamento alcuni raggiungono un’efficienza superiore al 90%. I ventilatori sono conformi agli standard industriali richiesti per ogni applicazione, ad esempio API, ATEX, certificazioni nucleari.

Gamma di prodotti

La gamma di ventilatori assiali comprende una serie di prodotti sviluppati da diversi marchi attuali e storici di Howden per offrire una copertura completa delle esigenze di portata e pressione di livello industriale.

Questa gamma ci permette di affrontare molte applicazioni con configurazioni alternative, verticali o orizzontali, e diverse opzioni di controllo delle portate, dal passo regolabile manualmente al passo variabile e agli azionamenti a frequenza variabile.

Tutti i ventilatori sono costruiti secondo standard elevati per garantire un funzionamento efficiente e una manutenzione ridotta con un servizio affidabile.

Gamma di prodotti

La nostra gamma di ventole di raffreddamento è composta dalle serie D, E, SX e FPX e offre prestazioni eccezionali in termini di efficienza e livelli di rumorosità in una serie di settori diversi, dagli impianti di alimentazione, petroliferi e del gas agli impianti di produzione industriale leggera, ai data center, agli edifici commerciali e ai motori di macchinari industriali.

La gamma di ventilatori copre un’ampia serie di prestazioni con una bassa caduta di pressione fino a 250 Pa e un’elevata portata d’aria fino a 3000 m3/s. Offre livelli di rumorosità da bassi a bassissimi per massimizzare l’uscita nel rispetto delle normative del sito.

Per ulteriori informazioni sulla gamma, visita la nostra pagina dedicata ai ventilatori di raffreddamento e accedi alla nostra documentazione di marketing.

I nostri servizi di assistenza comprendono tutti i ventilatori assiali, dai marchi propri a quelli di altri produttori.

Per i nostri marchi di ventilatori offriamo una gamma completa di soluzioni post-vendita, dai componenti di ricambio OEM, l’analisi, la risoluzione dei problemi e la manutenzione generale, fino agli aggiornamenti e ai retrofit completamente progettati per le prestazioni operative e l’estensione della vita utile.

I nostri marchi includono quelli attualmente disponibili come nuove apparecchiature quali Howden e Alphair, ma anche quelli acquisiti nel corso dei nostri 160 anni di storia, come Buffalo Forge, Turbowerke Meisen e Nordisk.

Accesso alla documentazione di marketing disponibile

Telefono +44 141 885 7500