Scambiatori di calore rotanti

I riscaldatori di gas e i preriscaldatori d’aria Howden recuperano calore che altrimenti verrebbe sprecato, svolgendo un ruolo vitale e aumentando l’efficienza energetica in una serie di processi industriali.

Sin dalla nascita di questa tecnologia, cioè da più di cent’anni, Howden è all’avanguardia nel migliorare l’efficienza degli impianti di alimentazione a caldaia e delle attività industriali con riscaldatori a combustione. Già negli anni ’30 del secolo scorso, il riscaldatore è stato applicato ai sistemi FGD e da allora ai sistemi SCR per ottimizzare i controlli delle emissioni.

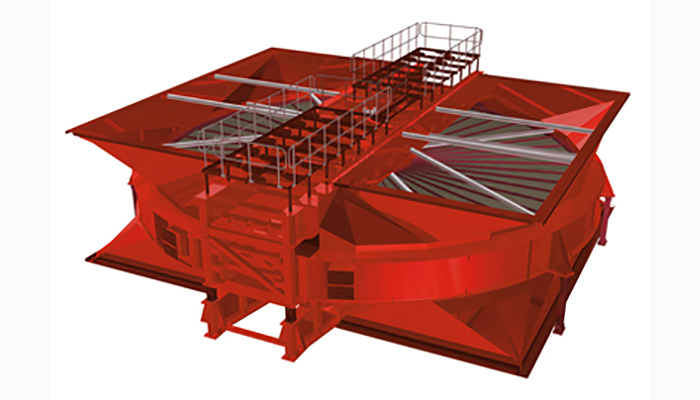

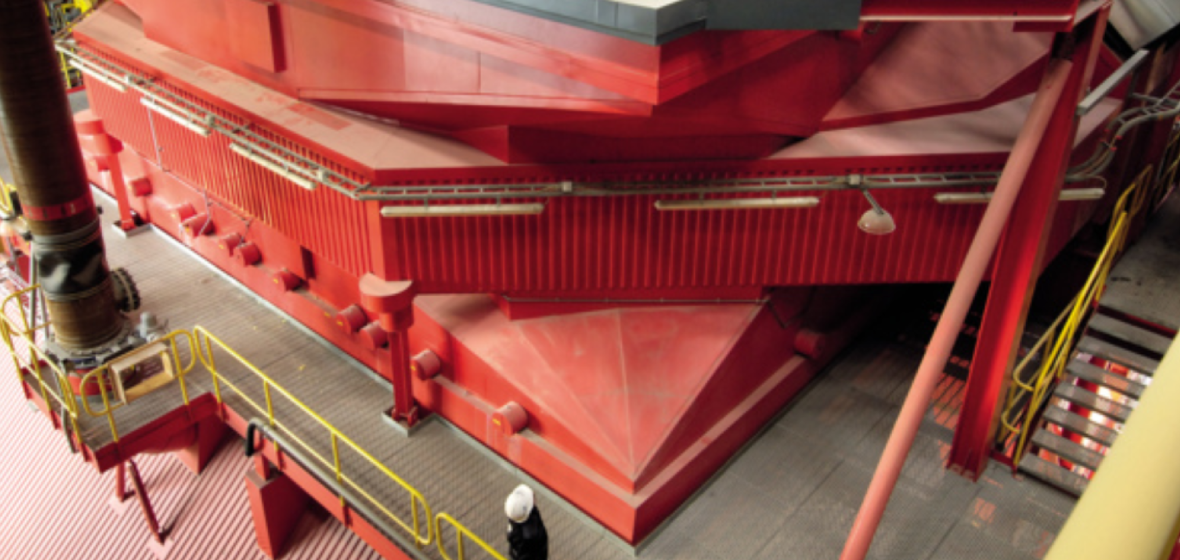

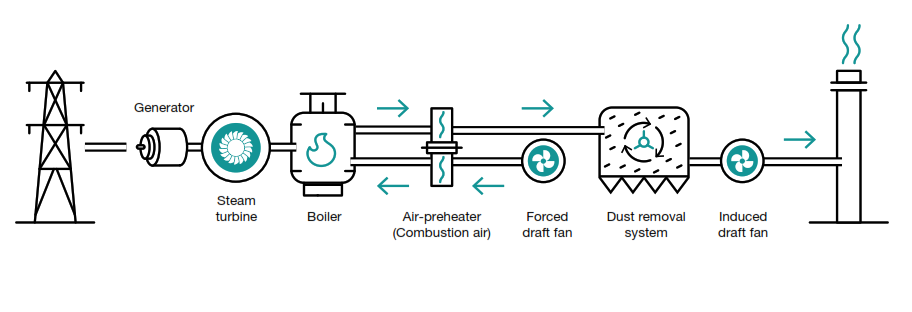

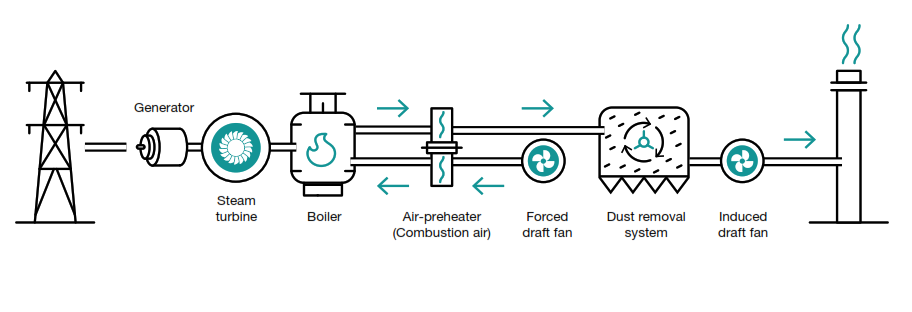

I preriscaldatori d’aria rigenerativi estraggono il calore residuo dai gas di scarico all’uscita del forno e trasferiscono questa energia all’aria in ingresso utilizzata nel forno per fornire l’ossigeno necessario all’accensione del combustibile.

Mentre il preriscaldatore ruota lentamente a circa 1-2 giri/min, sottili elementi metallici per il trasferimento del calore assorbono l’energia termica dal flusso di gas caldo e la trasferiscono al flusso di aria fredda in entrata.

Obiettivo: aumentare del 10-15% l’efficienza della caldaia, del forno o della stufa.

Tipici processi serviti

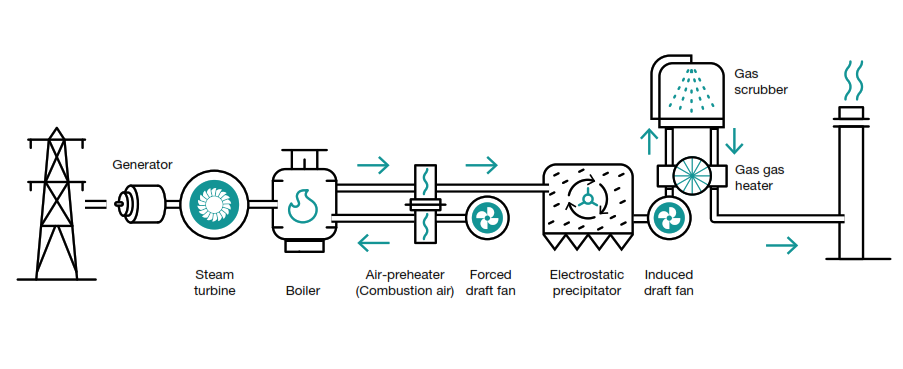

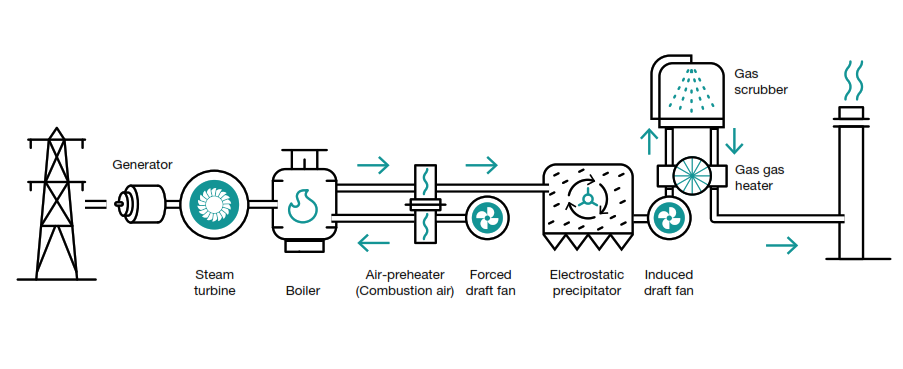

Il biossido di zolfo è un gas acido nocivo emesso durante la combustione dei combustibili fossili. Con l’introduzione della tecnologia di desolforazione dei gas di scarico (FGD) per il controllo delle emissioni mediante lavaggio del gas, il riscaldatore rotante ha trovato un’altra preziosa applicazione.

Molti sistemi FGD sono progettati con riscaldatori di gas (GGH) per ridurre la temperatura dei fumi prima dell’adsorbitore e riscaldare nuovamente il gas trattato, producendo una canna di scarico “asciutta”. Ciò garantisce un galleggiamento sufficiente del pennacchio di fumo e impedisce che le concentrazioni di SO2 a livello del suolo salgano oltre i limiti specificati.

Il GGH riduce il consumo di acqua nell’adsorbitore ed elimina lo scarico del liquido nella canna di scarico. Inoltre, evita gli elevati costi di ristrutturazione della canna e i problemi di manutenzione causati dall’azione corrosiva degli acidi e dall’ostruzione degli scarichi.

I riscaldatori a gas rigenerativi recuperano energia dal gas non trattato in entrata nello scrubber FGD assorbendo il calore residuo in sottili elementi metallici di trasferimento del calore. Gli elementi tipicamente ruotano a circa 0,5-1 giri/min trasferendo il calore al gas trattato che viene inviato alla canna di scarico.

Obiettivo: facilitare il processo di trattamento SOX e ridurre i costi riscaldando il gas trattato al livello di galleggiamento richiesto.

Tipici processi serviti

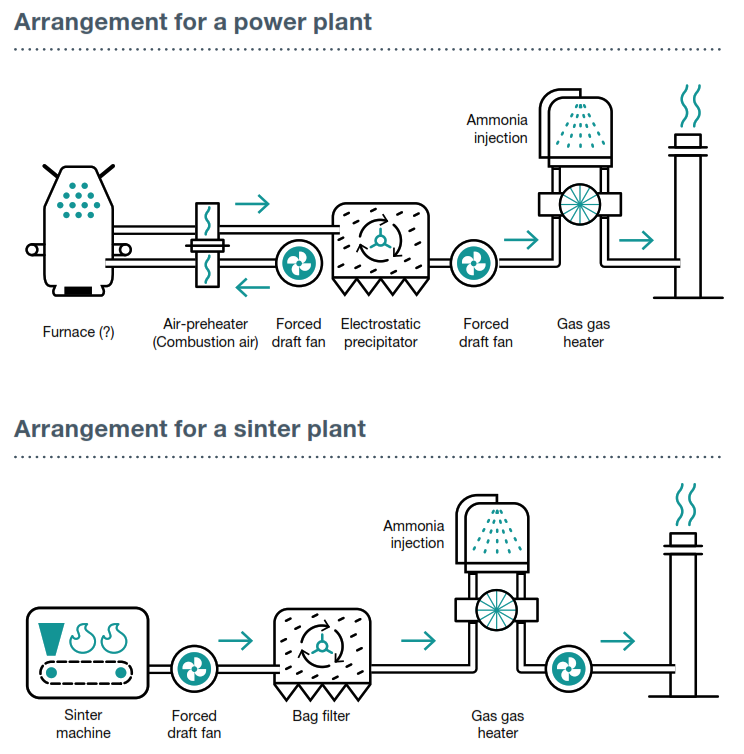

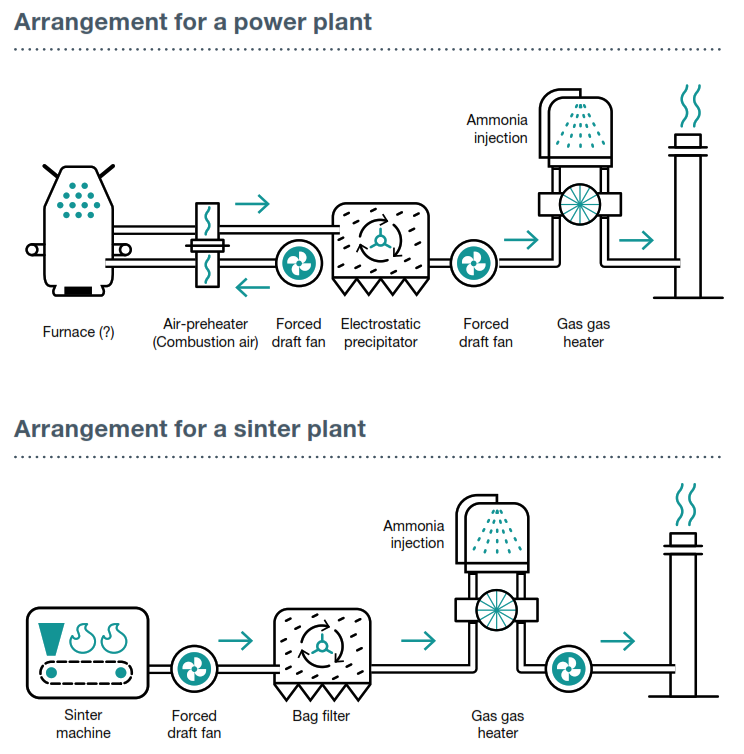

L’ossido di azoto è un gas nocivo emesso durante la combustione dei combustibili fossili. Con l’introduzione della tecnologia di riduzione catalitica selettiva (SCR) per il controllo delle emissioni, il riscaldatore rotante ha trovato un’altra preziosa applicazione.

In alcuni impianti, dove il sistema SCR non può essere installato sull’economizzatore, viene utilizzato il sistema SCR a basse polveri (o di coda) per ridurre le emissioni di NOx.

I riscaldatori a gas (GGH) rigenerativi recuperano energia dal gas trattato in uscita da sistema SCR assorbendo il calore residuo in sottili elementi metallici di trasferimento del calore. In questa applicazione, gli elementi riscaldati ruotano a una velocità compresa tra 0,6-1 giri/min trasferendo il calore al gas di alimentazione non trattato, riducendo così il livello di riscaldamento aggiuntivo necessario per raggiungere la temperatura di reazione.

Obiettivo: aumentare l’efficienza del sistema di emissioni di NOX riducendo il riscaldamento aggiuntivo necessario per raggiungere la temperatura di reazione per la distruzione di NOX (≈ 250 - 330oC).

Tipici processi serviti

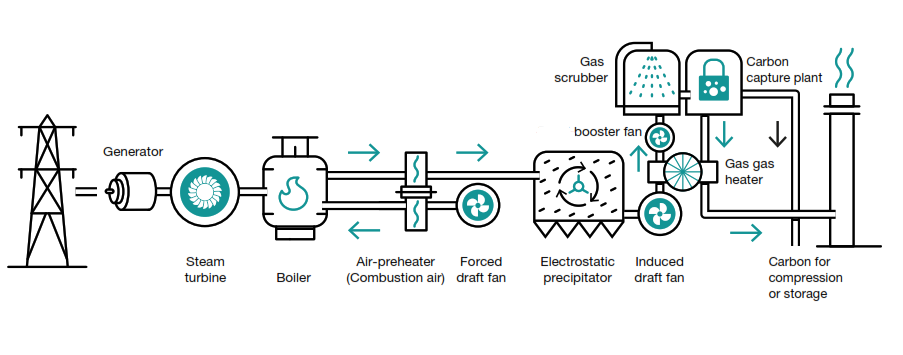

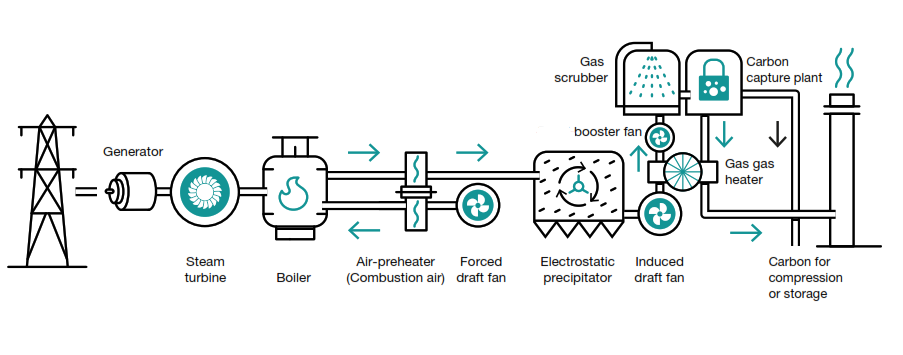

Con il passaggio del settore industriale verso la cattura e lo stoccaggio del carbonio, la tecnologia del riscaldatore rotante viene integrata nello sviluppo di soluzioni.

Gli impianti di cattura del carbonio post-combustione (PCC) possono essere sviluppati come parte di un impianto di alimentazione nuovo o ristrutturato. Tali impianti catturano il diossido di carbonio (CO2) nei gas di scarico per utilizzarlo come prodotto o per stoccarlo in depositi geologici sotterranei permanenti.

Il riscaldatore impiegato per questo processo è simile al riscaldatore a gas (GGH) con temperature simili al processo FGD. Il riscaldatore combina il raffreddamento dei gas di scarico prima dell’impianto FGD e il riscaldamento del gas trattato dopo l’impianto di cattura del carbonio per lo scarico verso la canna.

Obiettivo: abbassare la temperatura del gas non trattato prima dell’impianto di cattura e utilizzarlo per riscaldare nuovamente il gas trattato, ridurre la visibilità del pennacchio e avere un galleggiamento sufficiente per la fuoriuscita dalla canna di scarico.

Prodotti applicabili

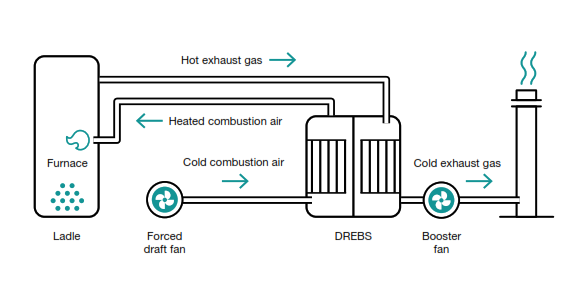

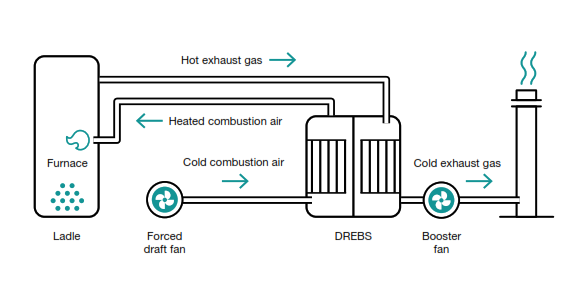

Molti processi industriali comportano la cottura ad alta temperatura. Questi processi sono estremamente energivori e quindi qualsiasi mezzo per abbattere i consumi può portare a notevoli risparmi operativi.

La soluzione di Howden proviene dal nostro marchio Rothemühle e al relativo riscaldatore DREBS. Si tratta di un sistema di bruciatori rigeneranti rotanti, in cui il riscaldatore assorbe energia dai gas di scarico ad alta temperatura sulle superfici riscaldanti in ceramica, che quindi ruotano per trasferire il calore al flusso d’aria.

Rispetto ai sistemi di recupero convenzionali, DREBS può essere utilizzato per temperature significativamente più elevate fino a 1200oC. Grazie all’elevata efficienza termica >85%, il risparmio energetico può essere raddoppiato rispetto ai sistemi di recupero.

Obiettivo: aumentare l’efficienza di bruciatori ed essiccatori fino al 100% rispetto ai sistemi di recupero.

Applicazioni tipiche

I preriscaldatori d’aria rigenerativi estraggono il calore residuo dai gas di scarico all’uscita del forno e trasferiscono questa energia all’aria in ingresso utilizzata nel forno per fornire l’ossigeno necessario all’accensione del combustibile.

Mentre il preriscaldatore ruota lentamente a circa 1-2 giri/min, sottili elementi metallici per il trasferimento del calore assorbono l’energia termica dal flusso di gas caldo e la trasferiscono al flusso di aria fredda in entrata.

Obiettivo: aumentare del 10-15% l’efficienza della caldaia, del forno o della stufa.

Tipici processi serviti

Il biossido di zolfo è un gas acido nocivo emesso durante la combustione dei combustibili fossili. Con l’introduzione della tecnologia di desolforazione dei gas di scarico (FGD) per il controllo delle emissioni mediante lavaggio del gas, il riscaldatore rotante ha trovato un’altra preziosa applicazione.

Molti sistemi FGD sono progettati con riscaldatori di gas (GGH) per ridurre la temperatura dei fumi prima dell’adsorbitore e riscaldare nuovamente il gas trattato, producendo una canna di scarico “asciutta”. Ciò garantisce un galleggiamento sufficiente del pennacchio di fumo e impedisce che le concentrazioni di SO2 a livello del suolo salgano oltre i limiti specificati.

Il GGH riduce il consumo di acqua nell’adsorbitore ed elimina lo scarico del liquido nella canna di scarico. Inoltre, evita gli elevati costi di ristrutturazione della canna e i problemi di manutenzione causati dall’azione corrosiva degli acidi e dall’ostruzione degli scarichi.

I riscaldatori a gas rigenerativi recuperano energia dal gas non trattato in entrata nello scrubber FGD assorbendo il calore residuo in sottili elementi metallici di trasferimento del calore. Gli elementi tipicamente ruotano a circa 0,5-1 giri/min trasferendo il calore al gas trattato che viene inviato alla canna di scarico.

Obiettivo: facilitare il processo di trattamento SOX e ridurre i costi riscaldando il gas trattato al livello di galleggiamento richiesto.

Tipici processi serviti

L’ossido di azoto è un gas nocivo emesso durante la combustione dei combustibili fossili. Con l’introduzione della tecnologia di riduzione catalitica selettiva (SCR) per il controllo delle emissioni, il riscaldatore rotante ha trovato un’altra preziosa applicazione.

In alcuni impianti, dove il sistema SCR non può essere installato sull’economizzatore, viene utilizzato il sistema SCR a basse polveri (o di coda) per ridurre le emissioni di NOx.

I riscaldatori a gas (GGH) rigenerativi recuperano energia dal gas trattato in uscita da sistema SCR assorbendo il calore residuo in sottili elementi metallici di trasferimento del calore. In questa applicazione, gli elementi riscaldati ruotano a una velocità compresa tra 0,6-1 giri/min trasferendo il calore al gas di alimentazione non trattato, riducendo così il livello di riscaldamento aggiuntivo necessario per raggiungere la temperatura di reazione.

Obiettivo: aumentare l’efficienza del sistema di emissioni di NOX riducendo il riscaldamento aggiuntivo necessario per raggiungere la temperatura di reazione per la distruzione di NOX (≈ 250 - 330oC).

Tipici processi serviti

Con il passaggio del settore industriale verso la cattura e lo stoccaggio del carbonio, la tecnologia del riscaldatore rotante viene integrata nello sviluppo di soluzioni.

Gli impianti di cattura del carbonio post-combustione (PCC) possono essere sviluppati come parte di un impianto di alimentazione nuovo o ristrutturato. Tali impianti catturano il diossido di carbonio (CO2) nei gas di scarico per utilizzarlo come prodotto o per stoccarlo in depositi geologici sotterranei permanenti.

Il riscaldatore impiegato per questo processo è simile al riscaldatore a gas (GGH) con temperature simili al processo FGD. Il riscaldatore combina il raffreddamento dei gas di scarico prima dell’impianto FGD e il riscaldamento del gas trattato dopo l’impianto di cattura del carbonio per lo scarico verso la canna.

Obiettivo: abbassare la temperatura del gas non trattato prima dell’impianto di cattura e utilizzarlo per riscaldare nuovamente il gas trattato, ridurre la visibilità del pennacchio e avere un galleggiamento sufficiente per la fuoriuscita dalla canna di scarico.

Prodotti applicabili

Molti processi industriali comportano la cottura ad alta temperatura. Questi processi sono estremamente energivori e quindi qualsiasi mezzo per abbattere i consumi può portare a notevoli risparmi operativi.

La soluzione di Howden proviene dal nostro marchio Rothemühle e al relativo riscaldatore DREBS. Si tratta di un sistema di bruciatori rigeneranti rotanti, in cui il riscaldatore assorbe energia dai gas di scarico ad alta temperatura sulle superfici riscaldanti in ceramica, che quindi ruotano per trasferire il calore al flusso d’aria.

Rispetto ai sistemi di recupero convenzionali, DREBS può essere utilizzato per temperature significativamente più elevate fino a 1200oC. Grazie all’elevata efficienza termica >85%, il risparmio energetico può essere raddoppiato rispetto ai sistemi di recupero.

Obiettivo: aumentare l’efficienza di bruciatori ed essiccatori fino al 100% rispetto ai sistemi di recupero.

Applicazioni tipiche

Howden si occupa di riscaldatori rotanti rigenerativi da quando ha sottoscritto una joint venture con il loro inventore, Fredrik Ljungström, nel 1923. La nostra tecnologia ha visto miglioramenti di progettazione attraverso la ricerca, lo sviluppo e l’analisi continui per ottimizzare le prestazioni e l’affidabilità dei prodotti.

Nel 2021 è stato aggiunto il marchio Rothemühle che ha portato con sé quasi 90 anni di esperienza nel settore dei riscaldatori.

Le nostre capacità spaziano dalle azioni volte a garantire che la nostra vasta base globale di riscaldatori continui a operare al servizio dei nostri clienti, fino all'adattamento delle tecnologie per soddisfare nuove esigenze industriali.

I nostri riscaldatori offrono un’operatività continuativa con intervalli di manutenzione ridotti. Per preservare prestazioni ottimali, disponiamo di un team globale di ingegneri pronti ad assicurare interventi di manutenzione per tutti gli scambiatori di calore rotanti dei nostri marchi, cioè Howden, Sirocco, Tallares Sanchez Luengo (TSL) e Rothemühle (incluso LUGAT).

Poiché le condizioni di funzionamento dell’impianto possono cambiare nel corso degli anni, possiamo offrire una gamma di servizi di assistenza tecnica per valutare e implementare miglioramenti delle prestazioni ed estensioni della vita utile.

I riscaldatori di gas Howden operano su un’ampia gamma di volumi, temperature e ingombri per soddisfare le esigenze di più processi e configurazioni ingegneristiche.

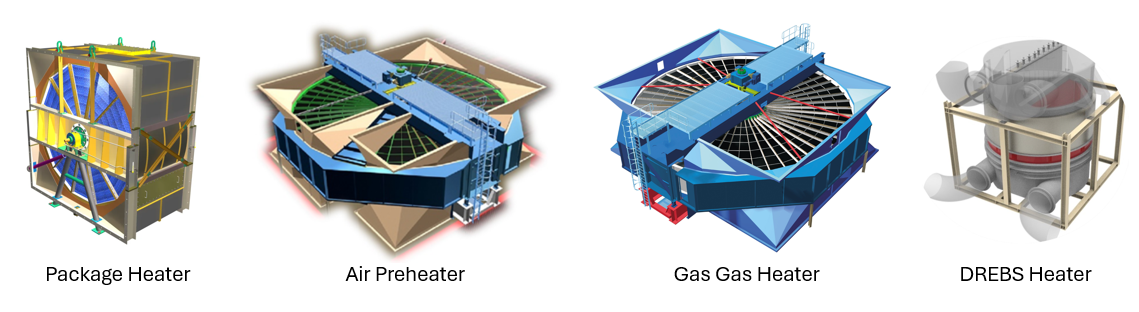

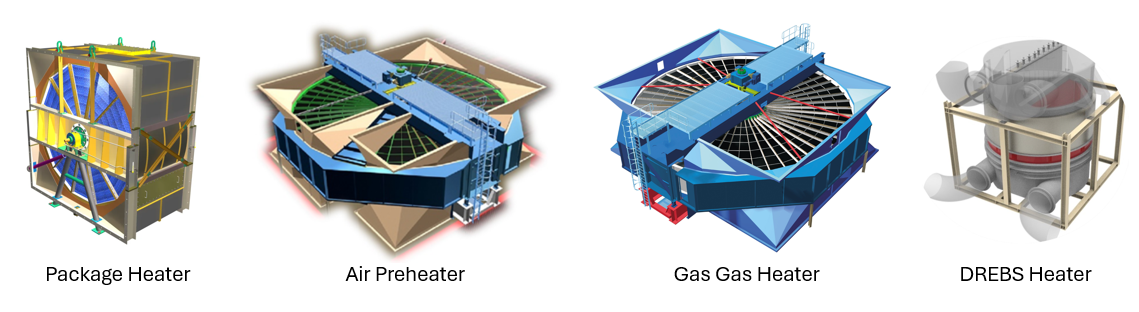

| Prodotto | Recupero di energia termica | Volume di gas | Temperature di gas | Ingombro | Perdite | Applicazioni |

|---|---|---|---|---|---|---|

| Riscaldatore a pacchetto | Fino a 15 MW | Da 45 a 200 tonnellate/h | Fino a 370oC (698oF) | Circa Da 3,5 m2 a 5,4 m2 | <5% utilizzando guarnizioni radiali singole/doppie e assiali doppie | Preriscaldamento dell’aria su scala ridotta |

| Preriscaldatore d’aria | fino a 100 MW | Da 200 a 3600 tonnellate/h | Fino a 500oC (932oF) | Fino a 625 m2 | <5% utilizzando guarnizioni multiple a labirinto con piastre di settori opzionali | Preriscaldamento dell’aria a grandi volumi |

| Riscaldatore a gas | fino a 100 MW | Da 200 a 3600 tonnellate/h | Fino a 500oC (932oF) | Fino a 625 m2 | <0,5% utilizzando guarnizioni multiple a labirinto, sistemi di spurgo e pulizia con piastre di settori opzionali | Riscaldamento del gas per FGD e preriscaldamento del gas per SCR |

| Riscaldatore DREBS | fino a 7 MW | fino a 40 tonnellate/h | Fino a 1200oC (2192oF) | fino a 16 m2 | Variabile in base alla pressione e all’applicazione | Recupero di energia ad alta temperatura per applicazioni in metallo, vetro e forno |

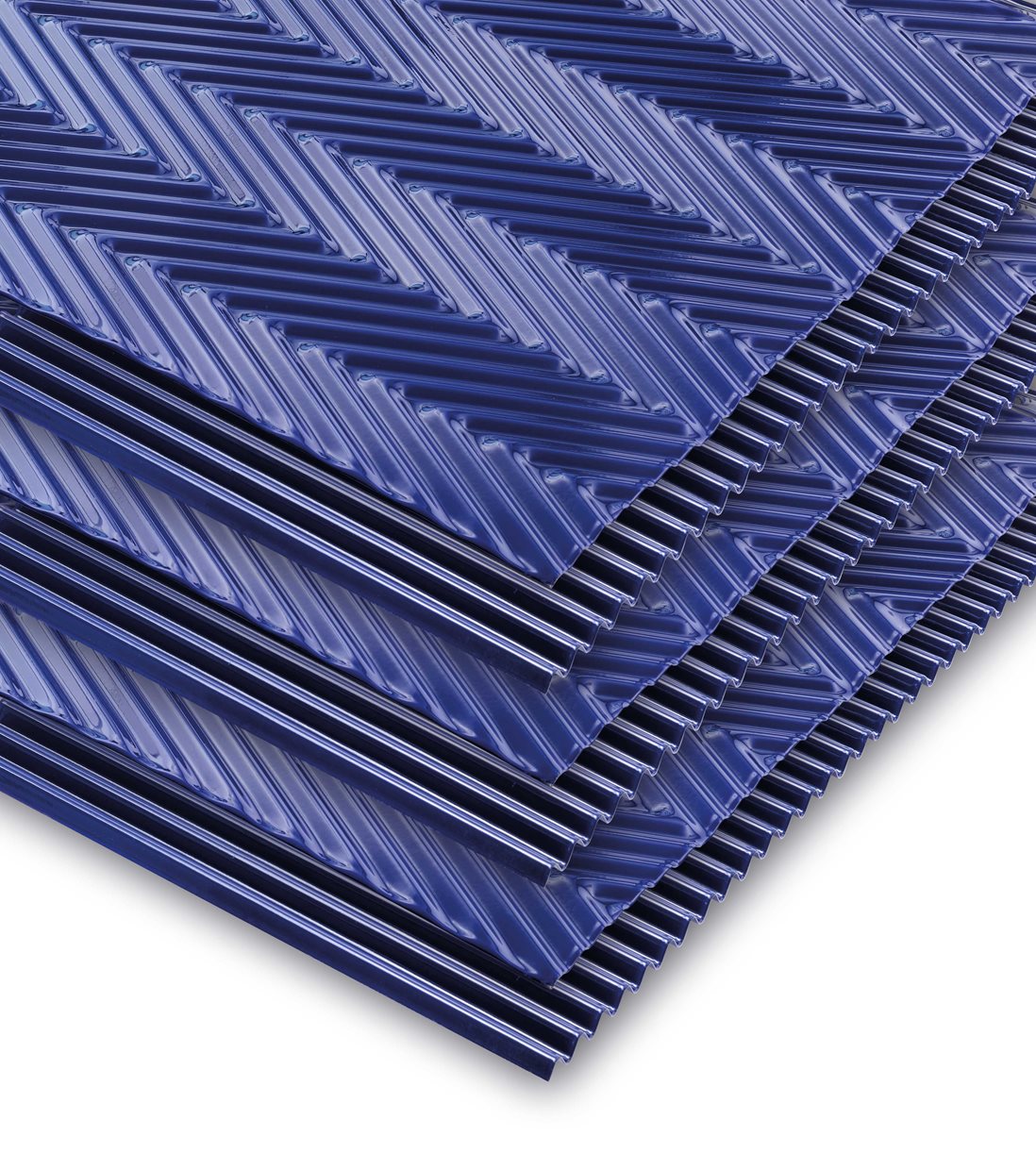

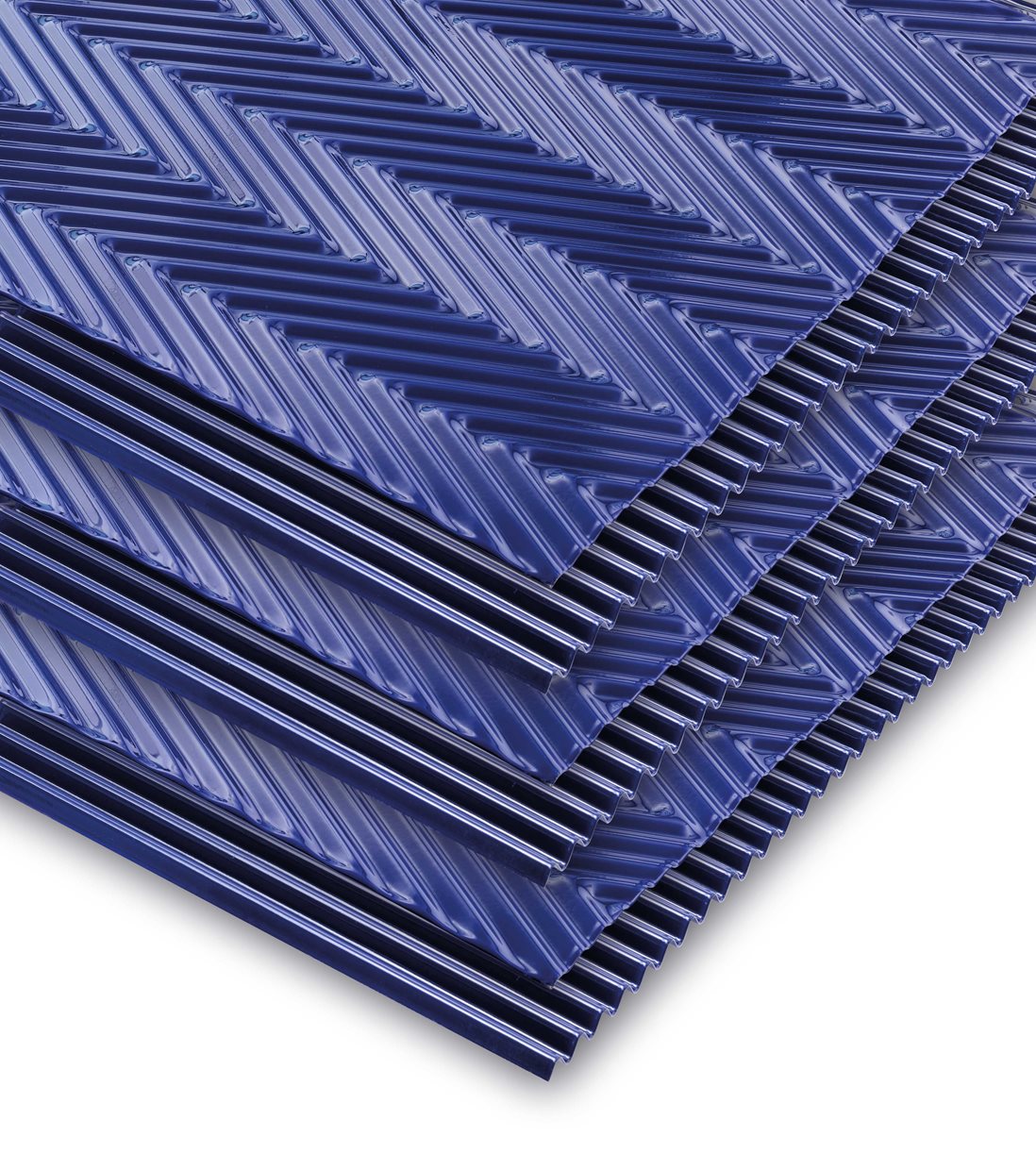

Mantenere la massima efficienza richiede una conoscenza approfondita delle modalità di funzionamento del riscaldatore nel tempo con ogni particolare tipo di carburante. Gli elementi di trasferimento del calore sono progettati specificamente per ciascuna applicazione e combustibile.

La nostra ampia gamma di prodotti ci permette di offrire il giusto equilibrio tra prestazioni termodinamiche, cadute di pressione e facilità di pulizia per ogni situazione. I profili possono essere scelti dalla nostra gamma (che comprende il primo elemento a doppio profilo disponibile in commercio al mondo) oppure possiamo abbinare i profili già esistenti.

Siamo leader mondiali nella produzione di elementi smaltati che offrono una combinazione di protezione dalla corrosione e di buona pulizia quando vengono utilizzati in ambienti rigorosi.

Gli elementi giocano un ruolo fondamentale nelle prestazioni del riscaldatore, ma attraverso un approccio sistematico alla scienza del ciclo di contaminazione e pulizia, abbiamo sviluppato un sistema integrato che offre molto più della somma delle parti:

SureCoat™ (smaltatura ad alte prestazioni) + SurePack™ (imballaggio di elementi ottimizzato) + Enerjet™ (sistema di pulizia avanzato).

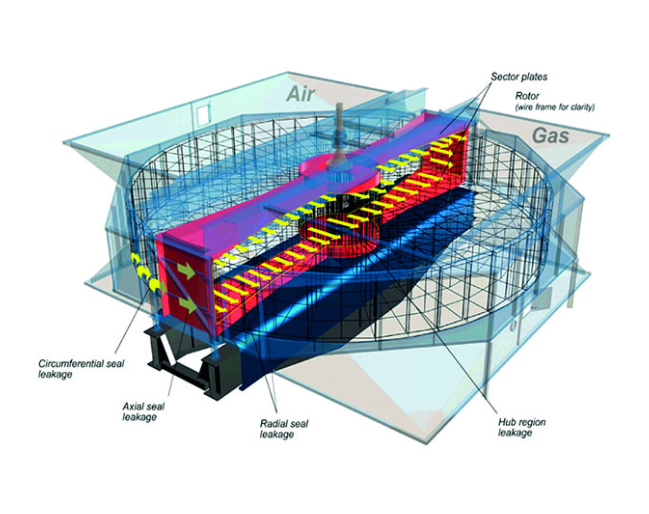

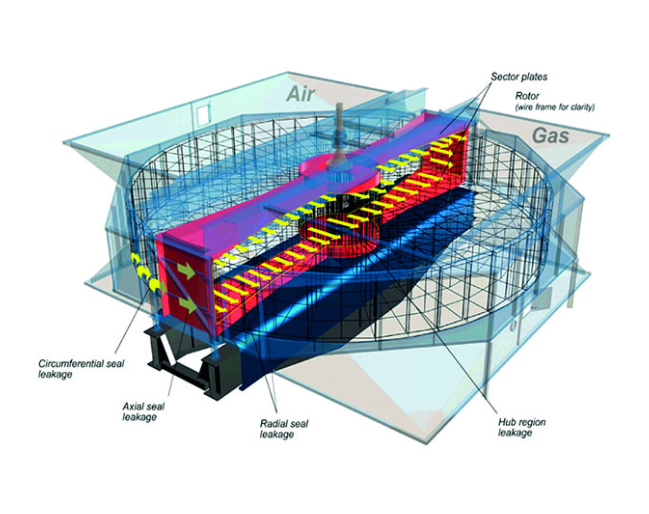

La riduzione al minimo delle perdite di gas è un aspetto fondamentale per il quale Howden ha sviluppato una serie di soluzioni innovative.

Il sistema di tenuta VN mantiene costantemente al minimo le perdite per periodi prolungati. Per i GGH vengono adottati metodi aggiuntivi come la pressurizzazione dello spazio di tenuta tramite gas pulito, utilizzando una ventola di spurgo per creare una leggera differenza di pressione. Un sistema di pulizia espelle quindi il gas sporco dagli elementi utilizzando gas trattato.

Guarnizioni di contattoLe guarnizioni di contatto flessibili per gli scambiatori di calore rotanti sono un metodo per ridurre al minimo le perdite dirette tra l’estremità calda del rotore e le piastre divisorie che separano i flussi di aria e gas.

Le guarnizioni standard si guastano a causa della costante flessione, pertanto Howden ha condotto un ampio programma di sviluppo per ottimizzare le guarnizioni di contatto per le applicazioni più adatte, riducendo notevolmente le perdite. Poiché le guarnizioni funzionano al meglio in situazioni in cui le fessure sono piccole e uniformi, la riduzione delle perdite può essere ulteriormente migliorata combinandole con piastre divisorie paraboliche.

Piastre divisorie parabolicheLa crescente attenzione all’ambiente e la richiesta dei massimi livelli di efficienza hanno spinto Howden a sviluppare delle piastre divisorie paraboliche (in attesa di brevetto) da utilizzare con i nostri riscaldatori.

Le piastre divisorie con estremità calda sono progettate con una rigidità variabile per deformarsi a parabola, quando vengono azionate, per adattarsi alla forma del rotore operativo deformato. In questo modo si riduce al minimo la fessura di dispersione dell’estremità calda.

Le piastre divisorie paraboliche di Howden non solo riducono la potenza dei ventilatori nell’impianto, ma riducono anche il flusso di massa di gas verso le apparecchiature di riduzione delle emissioni a valle.

Negli scambiatori di calore rigenerativi rotanti, contrariamente a quanto accade negli scambiatori di calore recuperativi tubolari o a piastre, le incrostazioni non causano il deterioramento del trasferimento di calore. Le incrostazioni, però, aumentano i differenziali di pressione e di conseguenza la potenza dei ventilatori e le perdite. Mantenendo gli elementi puliti, tuttavia, la disponibilità rimane elevata e si riducono le esigenze di manutenzione ai soli servizi programmati.

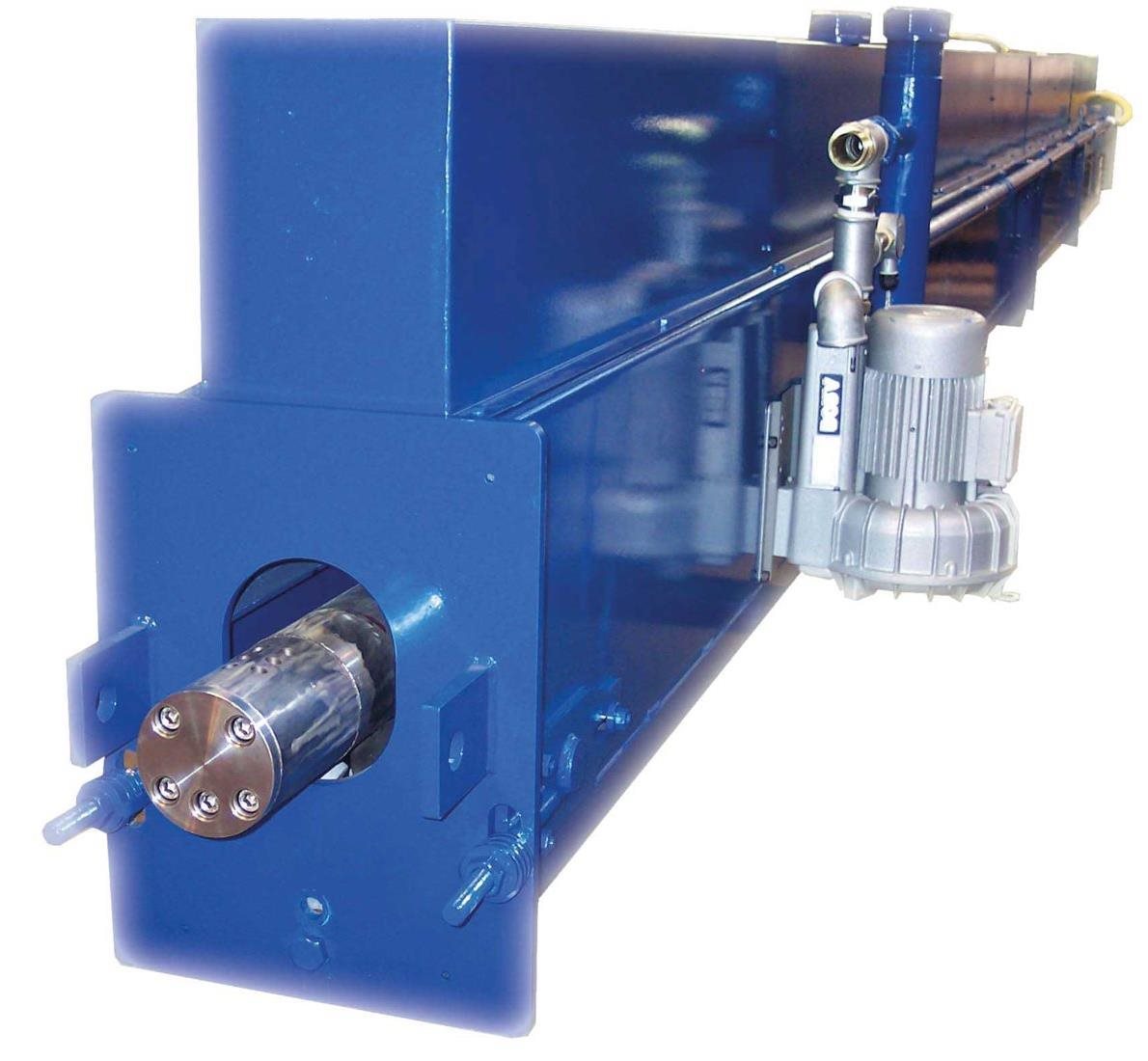

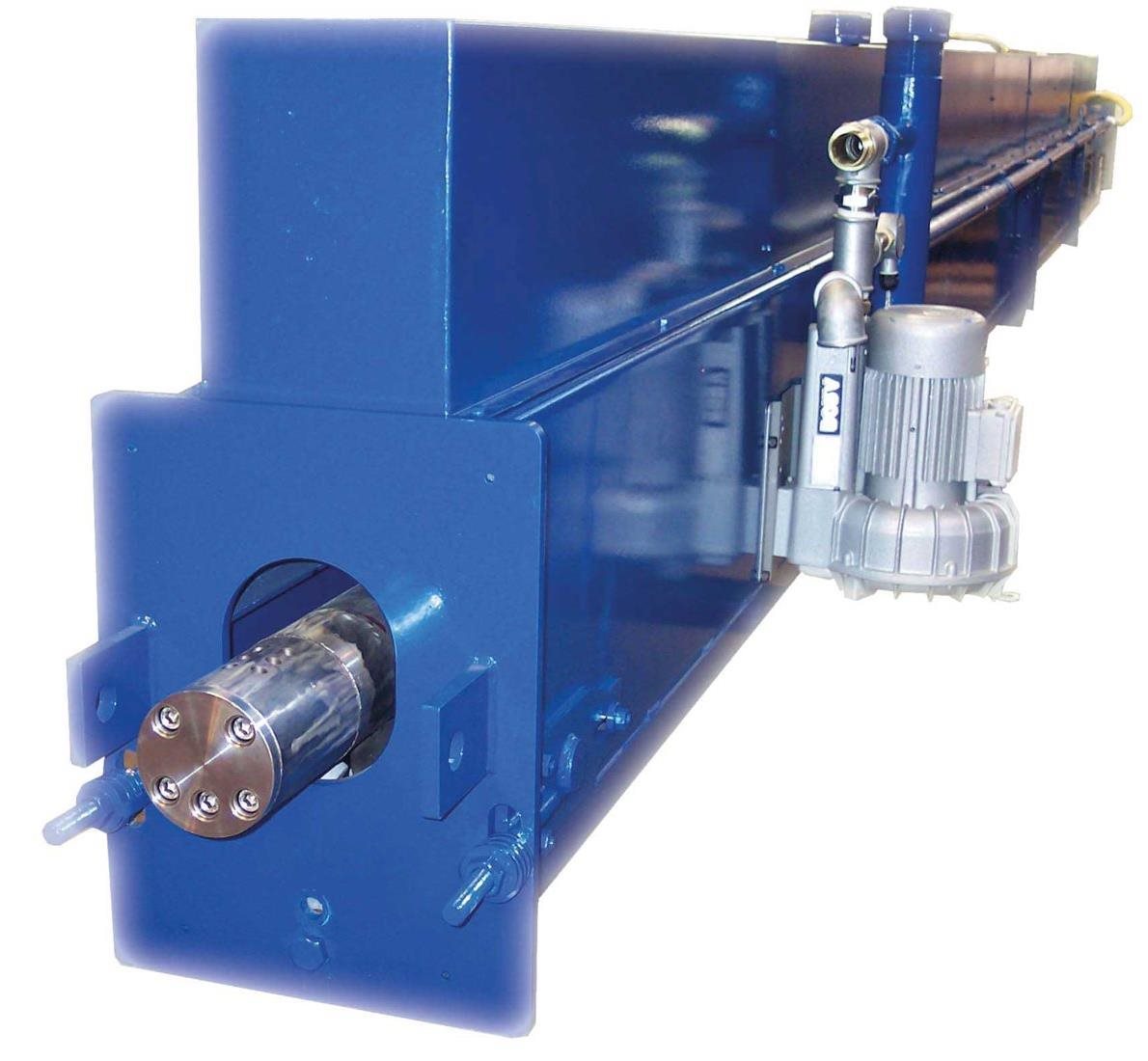

Il sistema di pulizia Enerjet™ di Howden è un metodo di lavaggio in linea ad acqua ad alta pressione dei preriscaldatori d’aria progettato per fornire una pulizia efficace ed efficiente degli elementi degli scambiatori di calore estremamente sporchi durante il normale utilizzo del preriscaldatore d’aria.

Il sistema Enerjet™ può essere utilizzato con qualsiasi tipo di preriscaldatore d’aria di qualsiasi produttore e funziona bene con la maggior parte dei profili degli elementi.

Enerjet™, in combinazione con SureCoat™ (elementi smaltati ad alte prestazioni) e SurePack™ (imballaggio degli elementi ottimizzati), rappresenta un approccio sistematico al ciclo di contaminazione e pulizia, offrendo più della somma delle parti.

I riscaldatori di gas Howden operano su un’ampia gamma di volumi, temperature e ingombri per soddisfare le esigenze di più processi e configurazioni ingegneristiche.

| Prodotto | Recupero di energia termica | Volume di gas | Temperature di gas | Ingombro | Perdite | Applicazioni |

|---|---|---|---|---|---|---|

| Riscaldatore a pacchetto | Fino a 15 MW | Da 45 a 200 tonnellate/h | Fino a 370oC (698oF) | Circa Da 3,5 m2 a 5,4 m2 | <5% utilizzando guarnizioni radiali singole/doppie e assiali doppie | Preriscaldamento dell’aria su scala ridotta |

| Preriscaldatore d’aria | fino a 100 MW | Da 200 a 3600 tonnellate/h | Fino a 500oC (932oF) | Fino a 625 m2 | <5% utilizzando guarnizioni multiple a labirinto con piastre di settori opzionali | Preriscaldamento dell’aria a grandi volumi |

| Riscaldatore a gas | fino a 100 MW | Da 200 a 3600 tonnellate/h | Fino a 500oC (932oF) | Fino a 625 m2 | <0,5% utilizzando guarnizioni multiple a labirinto, sistemi di spurgo e pulizia con piastre di settori opzionali | Riscaldamento del gas per FGD e preriscaldamento del gas per SCR |

| Riscaldatore DREBS | fino a 7 MW | fino a 40 tonnellate/h | Fino a 1200oC (2192oF) | fino a 16 m2 | Variabile in base alla pressione e all’applicazione | Recupero di energia ad alta temperatura per applicazioni in metallo, vetro e forno |

Mantenere la massima efficienza richiede una conoscenza approfondita delle modalità di funzionamento del riscaldatore nel tempo con ogni particolare tipo di carburante. Gli elementi di trasferimento del calore sono progettati specificamente per ciascuna applicazione e combustibile.

La nostra ampia gamma di prodotti ci permette di offrire il giusto equilibrio tra prestazioni termodinamiche, cadute di pressione e facilità di pulizia per ogni situazione. I profili possono essere scelti dalla nostra gamma (che comprende il primo elemento a doppio profilo disponibile in commercio al mondo) oppure possiamo abbinare i profili già esistenti.

Siamo leader mondiali nella produzione di elementi smaltati che offrono una combinazione di protezione dalla corrosione e di buona pulizia quando vengono utilizzati in ambienti rigorosi.

Gli elementi giocano un ruolo fondamentale nelle prestazioni del riscaldatore, ma attraverso un approccio sistematico alla scienza del ciclo di contaminazione e pulizia, abbiamo sviluppato un sistema integrato che offre molto più della somma delle parti:

SureCoat™ (smaltatura ad alte prestazioni) + SurePack™ (imballaggio di elementi ottimizzato) + Enerjet™ (sistema di pulizia avanzato).

La riduzione al minimo delle perdite di gas è un aspetto fondamentale per il quale Howden ha sviluppato una serie di soluzioni innovative.

Il sistema di tenuta VN mantiene costantemente al minimo le perdite per periodi prolungati. Per i GGH vengono adottati metodi aggiuntivi come la pressurizzazione dello spazio di tenuta tramite gas pulito, utilizzando una ventola di spurgo per creare una leggera differenza di pressione. Un sistema di pulizia espelle quindi il gas sporco dagli elementi utilizzando gas trattato.

Guarnizioni di contattoLe guarnizioni di contatto flessibili per gli scambiatori di calore rotanti sono un metodo per ridurre al minimo le perdite dirette tra l’estremità calda del rotore e le piastre divisorie che separano i flussi di aria e gas.

Le guarnizioni standard si guastano a causa della costante flessione, pertanto Howden ha condotto un ampio programma di sviluppo per ottimizzare le guarnizioni di contatto per le applicazioni più adatte, riducendo notevolmente le perdite. Poiché le guarnizioni funzionano al meglio in situazioni in cui le fessure sono piccole e uniformi, la riduzione delle perdite può essere ulteriormente migliorata combinandole con piastre divisorie paraboliche.

Piastre divisorie parabolicheLa crescente attenzione all’ambiente e la richiesta dei massimi livelli di efficienza hanno spinto Howden a sviluppare delle piastre divisorie paraboliche (in attesa di brevetto) da utilizzare con i nostri riscaldatori.

Le piastre divisorie con estremità calda sono progettate con una rigidità variabile per deformarsi a parabola, quando vengono azionate, per adattarsi alla forma del rotore operativo deformato. In questo modo si riduce al minimo la fessura di dispersione dell’estremità calda.

Le piastre divisorie paraboliche di Howden non solo riducono la potenza dei ventilatori nell’impianto, ma riducono anche il flusso di massa di gas verso le apparecchiature di riduzione delle emissioni a valle.

Negli scambiatori di calore rigenerativi rotanti, contrariamente a quanto accade negli scambiatori di calore recuperativi tubolari o a piastre, le incrostazioni non causano il deterioramento del trasferimento di calore. Le incrostazioni, però, aumentano i differenziali di pressione e di conseguenza la potenza dei ventilatori e le perdite. Mantenendo gli elementi puliti, tuttavia, la disponibilità rimane elevata e si riducono le esigenze di manutenzione ai soli servizi programmati.

Il sistema di pulizia Enerjet™ di Howden è un metodo di lavaggio in linea ad acqua ad alta pressione dei preriscaldatori d’aria progettato per fornire una pulizia efficace ed efficiente degli elementi degli scambiatori di calore estremamente sporchi durante il normale utilizzo del preriscaldatore d’aria.

Il sistema Enerjet™ può essere utilizzato con qualsiasi tipo di preriscaldatore d’aria di qualsiasi produttore e funziona bene con la maggior parte dei profili degli elementi.

Enerjet™, in combinazione con SureCoat™ (elementi smaltati ad alte prestazioni) e SurePack™ (imballaggio degli elementi ottimizzati), rappresenta un approccio sistematico al ciclo di contaminazione e pulizia, offrendo più della somma delle parti.

Sede centrale +44 141 885 7500

Riscaldatori a pacchetto +34 968 32 00 64